- Home

- Products

- ►

- LED modules

- ►

- LED light quality

LED light quality

LED modules

“LEDs and progress go firmly hand in hand. But yesterday’s new developments are considered run of the mill today. That is why Tridonic uses its innovative capabilities to open up a whole new world of reliability that not only meets but regularly exceeds the expectations of its many and varied customers.”

Martin Werkovits

Head of R&D Competence Center Light Sources, Tridonic Jennersdorf GmbH

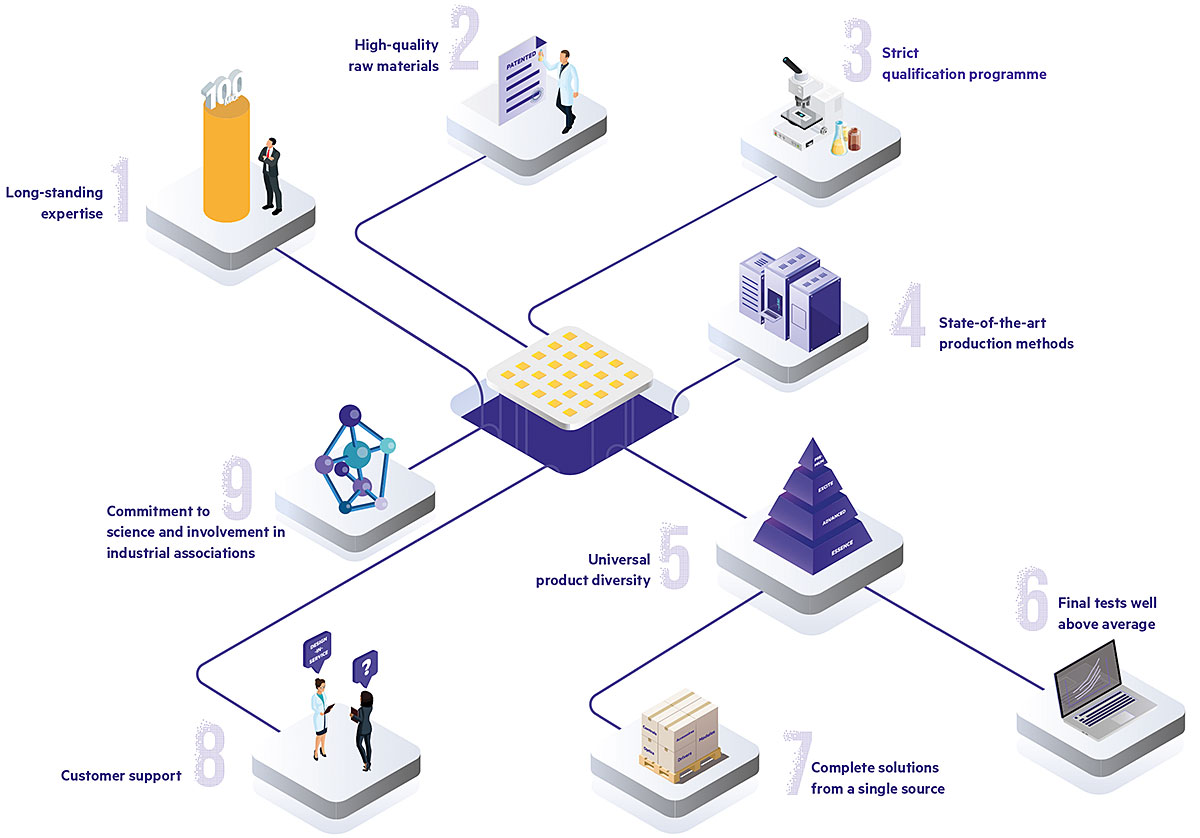

The reason Tridonic LED modules enjoy their leading position in the lighting industry: Technology+

1. Long-standing expertise

Since the year 2000, more than 100 million LED modules have left the European production site. This is an impressive statistic showing both expertise and experience. As a result, Tridonic has managed to establish itself as a trailblazer in the development of LED components. The company now has 1,600 employees and 74 locations all across the globe.

The experts at Tridonic are constantly pushing the boundaries of LED technology. Module series such as the SLE – now in its 7th generation and subject to consistent improvement – are the perfect proof. To date, Tridonic has patented more than 2,700 innovations.

Superb colour rendering

The tough Tridonic qualification programme ensures that Tridonic LED modules achieve optimum colour consistency (CRI and SDCM values). For evaluating the colour rendering and colorimetric locus, Tridonic also uses the latest alternatives to CRI, such as TM-30-15.

Special colours

Whether displaying food, fashion or works of art, the special colour SLE modules from Tridonic offer complete freedom meaning the perfect impression can be created with all sorts of objects.

2. High-quality raw materials

Right from the start, Tridonic insists on top quality to ensure outstanding technology of the highest level. All our raw materials (IP-free SMD LEDs, substrates, adhesives, phosphors, silicones, etc.) are sourced from carefully selected partners who have been identified via benchmarking. The reliability of each component is verified by carrying out a series of tests in accordance with the JEDEC standard. Depending on the result, the component is classified for various application areas.

3. Strict qualification programme

Tridonic’s qualification tests easily exceed the requirements of any standard.

All materials (such as substrates, adhesives, terminals and – of course – the LED packages) undergo additional qualification processes. Before the LED chips are turned into finished modules, they are tested and ranked on the basis of three categories:

Optical characteristics

To stop the performance deviating from that stated on the data sheet, Tridonic only accepts LEDs with golden sample verification. To determine the optoelectronic characteristics of the LEDs, their colour shift behaviour is tested at various current levels and operating temperatures (-40 °C to +120 °C).

Processing capacity

At Tridonic, quality assurance is not only performed on the finished products themselves, but as early as preliminary development. This ensures delivery capacity as well as production free of defects.

Reliability

In order to assess the LEDs in terms of their robustness, colour stability and mechanical stability, Tridonic relies – among other things – on a much higher number of cycles than usual across a vast array of testing methods.

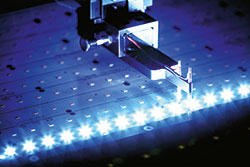

4. State-of-the-art production methods

Without exception, Tridonic manufactures its products to the highest European specifications. Various factors play a key role in quality, ensuring that the products can be made available quickly and reliably. These factors include the clean room atmosphere, highly automated SMD and COB facilities, and the highest degree of production flexibility.

Patented production methods

Tridonic uses a variety of techniques to make sure the modules can be operated efficiently and reliably, such as its patented method for fixing the dies on the board.

5. Universal product diversity

Thanks to the vast array of products in its range, Tridonic offers ideal solutions for various luminaire types – from spotlights and downlights, linear and flat luminaires to circular luminaires. The modules have been designed to support all kinds of applications. They cater just as fully for industrial environments as they do for shops, offices and educational establishments or outdoor settings. On request, Tridonic can supply luminaires to specification and can develop products according to individual requirements and preferences.

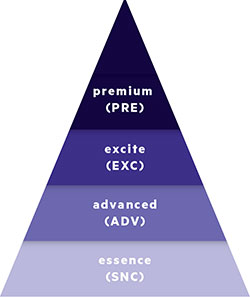

Four product categories

Each of the four categories exhibits specific characteristics that are tailored to a whole host of lighting tasks.

- premium (PRE):

Modules for exacting demands and tasks, such as the Tunable White technology for customisable light. - excite (EXC):

The solution for high-end lighting tasks – offering lighting scenes full of emotion, maximum flexibility and special colours. - advanced (ADV):

Combines high efficiency with outstanding quality of light. - essence (SNC):

Focuses on the core functions to meet the specifications of particular applications.

6. Final tests well above average

Before the LED modules leave the production site, they are subjected to a series of intensive final tests. This means, for example, that each Tridonic module meets the demanding tolerances of max. ±10 % for the luminous flux and efficacy. In this way, Tridonic also ensures that the products adhere to the defined colorimetric locus and stringent colour tolerances.

100 % test quota

Before proceeding with delivery to the customer, Tridonic checks each product at the factory for the following: luminous flux, electrical parameters, efficiency, colour temperature, CIE and MacAdam coordinates.

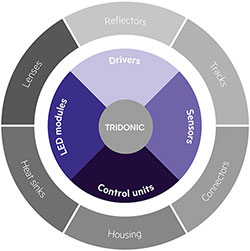

7. Complete solutions from a single source

Tridonic sees itself as a partner for luminaire manufacturers. For this reason, it offers comprehensive solutions rather than just individual components. All modules, drivers and control units are perfectly coordinated with one another to form an efficient unit.

By adding optional accessories, these solutions can then be customised and adapted to meet specific needs.

Tridonic cultivates close partnerships with suppliers of heat sinks, reflectors, lenses and luminaire housings. These products complement the Tridonic range perfectly and reduce development costs and effort for manufacturers.

Tridonic Setbuilder

With this handy web tool, the ideal combination of LED module and driver can be found quickly and easily.

8. Customer support

Direct contact

Local contacts are available at the branches to answer any technical queries.

Design-in service

Thanks to the design-in service, each component is able to master every technical challenge. What’s more, the Tridonic test reports offer support during luminaire certification.

Video about the Tridonic design-in service.

Comprehensive data

Tridonic provides its customers with the most detailed data sheets available on the market, making luminaire design a whole lot easier. In addition, it offers:

- LM 80 data

- RAY data

- Data on thermal behaviour

- Environmental compatibility statements

- CAD data

9. Commitment to science and involvement in industrial associations

Tridonic collaborates closely with national and international standardisation bodies. This keeps Tridonic constantly abreast of any changes and means that it is actively helping to shape the future of lighting technology. In turn, this saves luminaire manufacturers a great deal of work. Numerous research projects have already come about as a result of cooperation with research institutes, such as Joanneum Research and the Materials Center Leoben (MCL).

Certificates/Standards

LED modules – The countless facets of perfection

Further information:

Article & Interview in the German magazine "Elektropraxis":

Go to the German article: http://www.elektronikpraxis.vogel.de/